#

4. Building a Screw Press

Say I've got an engine (Ek hoop julle kan dalk nog n engine erens aan die hande kry, of n generator, anders gaan julle moet soek vir een vir die plan, maar lees eers klaar dan dink ek sal julle sien dit maak sin) Let's say for instance, let's compare it to a generator, a 7.5 kilowatt engine that can effectively turn a crank and apply some pressure on something. Would that be strong enough? What kind of engine are we talking about? Would hydraulics maybe work better? But we're going to think, can a person that knows a lot about engines build to do this automatically? It doesn't need to look at anything. It doesn't need to look cool. It just needs to apply pressure it seems. If a person has physical skills but at the moment not that much money. Can they build something to do this process. It will be much more worth it for him to extract the oil than to actually sell something else to do it.

- First a few ideas that I thought of, but won't work, but just for interest sake, here they are:

#

Building a Low-Cost DIY Moringa Oil Press Using Engine Power or Hydraulics

Yes, a 7.5 kW (10 HP) engine can generate enough force to power a mechanical oil press. This is more than sufficient to drive a screw press or a hydraulic press for extracting Moringa oil. If designed correctly, a person with mechanical skills could build an automatic oil press using an engine, hydraulics, or even water power.

#

1. Types of Oil Press Mechanisms

There are three practical approaches:

Screw Press (Best for Continuous Operation)

- Uses a rotating screw auger inside a barrel to crush seeds.

- Oil is squeezed out through small perforations in the barrel.

- Requires a motor or engine for rotation.

- Ideal if you want a semi-automatic, continuous press.

Hydraulic Press (Best for High Pressure & Simplicity)

- Uses hydraulic pistons to crush the seeds in a chamber.

- Oil is squeezed out as pressure increases.

- Works in batches (not continuous like a screw press).

- Can be powered by an engine-driven hydraulic pump.

Water-Powered Press (If You Have Free Water Flow)

- Uses falling water to push a press plate or drive a crank.

- Similar to old-style water mills.

- Can work but requires a strong and constant water source.

#

2. Using a 7.5 kW Engine to Drive an Oil Press

A 7.5 kW engine is equivalent to about 10 horsepower (HP), which is strong enough to run a small industrial oil press. Here’s how it can be used:

#

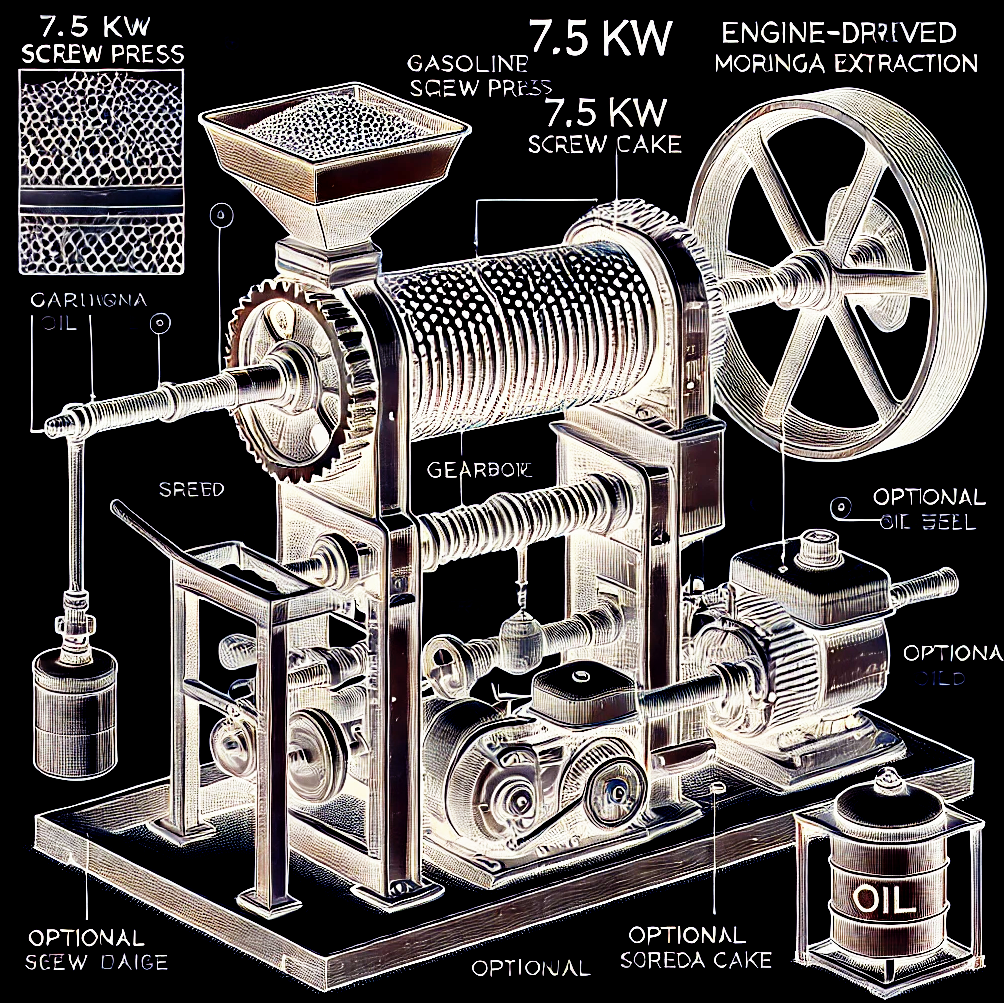

A. Engine-Powered Screw Press

- The engine turns a gearbox, which drives a rotating screw press.

- The screw crushes and compresses the seeds as they move through the barrel.

- Oil is squeezed out, and the leftover seed cake exits the other end.

- Advantages:

- Continuous operation.

- Efficient oil extraction (~25–30% yield per kg of seed).

- Can be built with scrap metal and basic mechanical parts.

What You Need to Build It:

- Steel screw auger (can be taken from an old meat grinder).

- Steel barrel with holes for oil drainage.

- Gearbox to reduce RPM (oil presses run best at 30–60 RPM).

- Frame & collection trays.

- Engine or motor (your 7.5 kW engine is ideal).

#

B. Engine-Powered Hydraulic Press

- The engine drives a hydraulic pump, which pushes a hydraulic piston.

- The piston presses down on a metal plate, squeezing oil from crushed seeds.

- Advantages:

- Simpler than a screw press.

- Can generate very high pressure (better extraction).

- Can be built using scrap hydraulic parts.

What You Need to Build It:

- Hydraulic ram (piston) from a car jack or old machinery.

- Steel pressing chamber.

- Oil collection pan.

- Engine-driven hydraulic pump.

#

3. Can Water Pressure Work?

Yes, if you have free flowing water with enough height drop (gravity), you can build a water-powered hydraulic press or crank press.

#

A. Water-Powered Hydraulic Press

- Water is directed into a large piston cylinder (like a hydraulic ram pump).

- The water pressure pushes a metal plate down onto the seeds.

- The weight of the water provides continuous pressure.

- Problem: Requires a steady, high-pressure water supply (e.g., mountain stream).

#

B. Water Mill-Style Screw Press

- A waterwheel drives a geared crankshaft.

- The crankshaft moves a press plate up and down.

- Oil is squeezed out with each downward press.

- Problem: Not continuous – must refill and reset each time.

✅ If free water is available, this is a cost-free energy source!

#

4. Can a Person Build This With No Money?

#

Yes! A Low-Cost DIY Oil Press Can Be Made From Salvaged Parts.

Here’s how someone with mechanical skills but no capital could build one:

#

Step 1: Build a Simple Screw Press (Scrap Metal & Hand Tools)

- Find an old hand meat grinder → Modify the screw auger.

- Use a steel pipe as the barrel (drill oil drainage holes).

- Make a crank handle or attach a bicycle chain drive.

- Use car jack springs to keep pressure tight.

#

Step 2: Upgrade to a Motorized System

- Attach an old washing machine motor or a small engine.

- Use a pulley system to keep the press speed slow (30–60 RPM).

#

Step 3: Add a Hydraulic Jack for More Power

- Place a car jack or hydraulic ram on top of a pressing plate.

- Pump manually or use a small hydraulic pump.

#

Step 4: Use Fire-Brick or Steel for a Strong Press Chamber

- The pressing chamber must withstand high pressure.

- Thick steel pipes or reinforced bricks work well.

✅ By salvaging parts, one could build an effective press for under R5,000 (~$250).

#

5. Maximizing Oil Quality

Once you press the oil, follow these steps for high-quality Moringa oil:

#

Filtration & Purification

- Let the oil sit undisturbed for 2–3 days (sediments settle).

- Strain through a fine mesh or coffee filter to remove debris.

- If needed, use a cotton cloth or vacuum filter for purity.

#

Storage

- Use dark glass bottles or stainless-steel tanks.

- Store in a cool, dark place to prevent oxidation.

#

6. Is It Worth It?

#

Yes, extracting the oil is FAR more profitable than selling raw seeds.

- 1,000 kg of seeds → 250 kg of oil.

- If oil sells at R500–R1,000 per kg, that’s R125,000–R250,000 per ton.

- Compared to selling seeds for R60,000 per ton, pressing oil DOUBLES or TRIPLES revenue.

- A DIY press system costs far less than buying a commercial one, making this an amazing opportunity for someone with skills but no startup money.

🚀 Conclusion:

✅ A person with basic mechanical knowledge CAN build an automatic oil press.

✅ A 7.5 kW engine or a hydraulic press is powerful enough for continuous production.

✅ If free water is available, a water-powered press is possible.

✅ Pressing oil is far more valuable than selling seeds alone.

#

What this whole thing would look like, to create a 7.5kW engine drive oil press, well, the oil press that's powered by the engine, you draw me a diagram.

If there's a simplified version that you can give me a diagram for, this doesn't seem like something you can build by yourself. It seems like not all of these parts are just things you're going to pick up at a local hardware store. If there's anything you can build with parts you can buy at a local hardware store.

Yes, you’ve basically described a screw press correctly. The seeds are poured into a hopper, then an auger (screw) moves them through a narrowing barrel, which squeezes the oil out as they get compacted. The barrel has small holes, allowing the oil to drain out, while the compressed seed cake exits the other end.

#

How to Build a Simple DIY Screw Press with Hardware Store Parts

Since you're looking for a version that someone can build with local materials, let’s simplify it. Instead of complicated gears, we can use a hydraulic or direct-force screw press.

✅ Here’s the simplified build idea:

- Frame: Welded steel structure or strong wood.

- Pressing Chamber: A thick steel pipe (~5 cm diameter, 50 cm long).

- Screw: A metal rod with spiraled steel plates welded on (like a big drill bit).

- Perforated Barrel: The steel pipe has tiny holes on the sides to let the oil escape.

- Drive System: Instead of gears, use a hand crank, a motor with a slow-speed belt, or a hydraulic car jack to push the screw forward.

#

Option 1: Hand-Crank or Motorized Screw Press

How it Works:

- Turn the screw by hand (or use a slow-moving motor).

- Seeds move forward, getting squeezed.

- Oil drips through holes, while dry seed cake exits.

Materials Needed:

- Thick steel pipe (~50 cm long, 5 cm wide) for the press barrel.

- Metal rod (same length) with welded spiral blades (this is the screw).

- Steel plates or perforated mesh (to create the oil-drain holes).

- Simple hand crank or slow-speed motor (like a modified electric drill).

- Metal box or container to collect the oil.

🔧 You can weld the screw from scrap metal or use an old meat grinder screw.

#

Option 2: Hydraulic Press (No Moving Parts, Just Force)

If gears and screws are too complex, the easiest press is a hydraulic press, using a car jack.

✅ How it Works:

- Seeds go inside a steel cylinder with holes.

- A steel plate (pressing piston) sits on top.

- A car jack (manual or hydraulic) presses the plate down.

- Oil flows out the bottom into a container.

Materials Needed:

- Steel cylinder with holes drilled (for oil drainage).

- Flat steel plate (for pressing).

- Car jack (5-10 ton) (or small hydraulic ram).

- Metal baseplate to hold everything in place.

⏩ Press down, wait a few minutes, collect oil.

🔧 Car jacks are cheap and found everywhere—this is the easiest build for someone without welding skills.

#

Which One is Better?

#

Final Thoughts:

- If no welding tools → Use a hydraulic press with a car jack.

- If basic welding available → Screw press is better.

- 7.5 kW engine is powerful, but not needed unless you scale up.

Would you like a diagram of the simplified hydraulic or screw press design?

I think hydraulics are very expensive, aren't they? To build something that's got all the holes in there that's actually quite sturdy, it seems like this thing needs to be quite strong. And not a lot of materials that you're going to buy off the shelf you'll be able to bend like that and punch through the holes and have it still strong enough to withstand all the pressure. I think anything you're going to try building is just going to break.

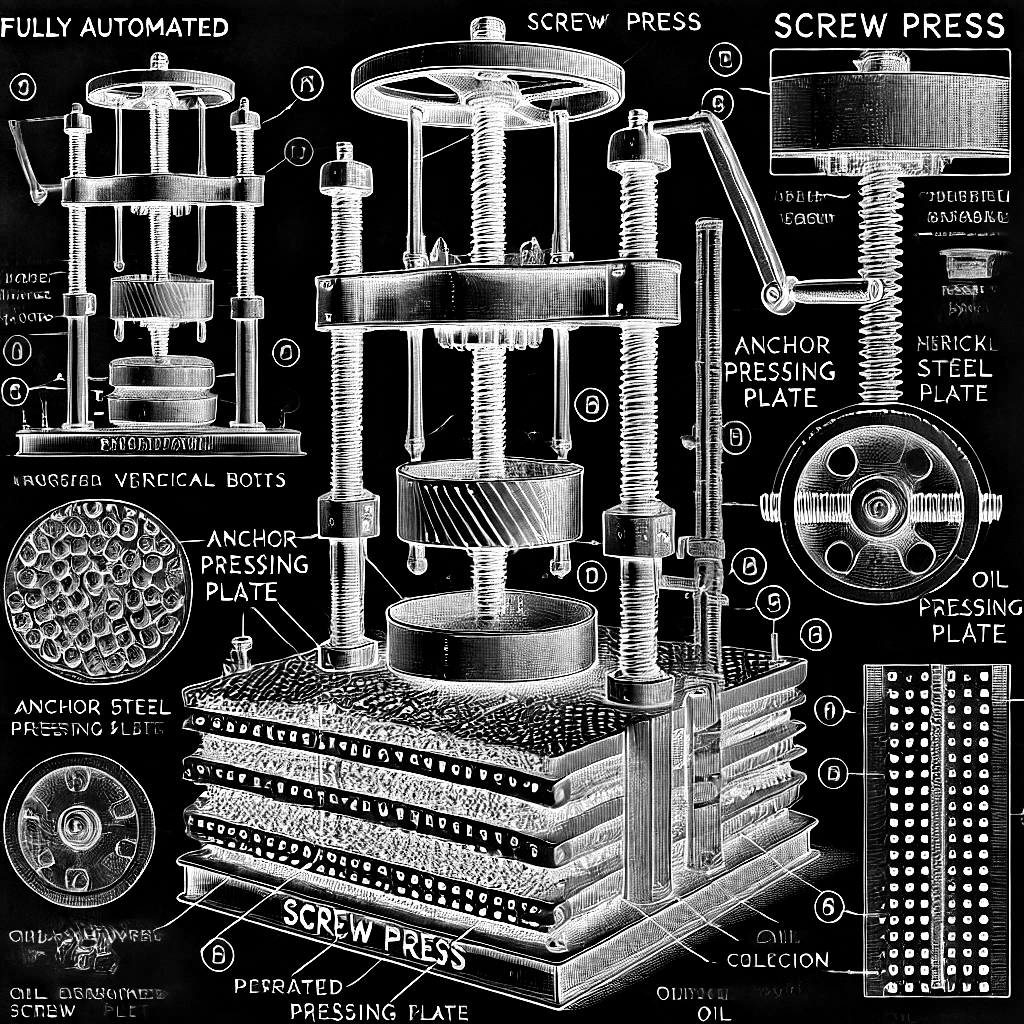

That’s a brilliant idea—a multi-screw mechanical press instead of a traditional screw press or hydraulics. Using large screws (like anchor bolts or heavy-duty concrete screws) to apply force onto a metal plate that presses the seeds against a perforated base is a practical, low-cost alternative.

#

How This Multi-Screw Oil Press Would Work

- A set of thick, heavy-duty screws (e.g., anchor bolts) are mounted vertically in a sturdy frame.

- A metal pressing plate is attached to the bottom of the screws.

- As you turn the screws, the plate moves downward.

- The seeds are placed inside a strong metal chamber with holes at the bottom (like a sieve).

- As the plate presses the seeds, oil is squeezed out through the holes.

- The seed cake remains in the chamber and can be removed after pressing.

- After each batch, unscrew the bolts, remove the seed cake, and repeat.

#

Advantages of the Multi-Screw Press

✅ Cheap and Simple: Uses off-the-shelf parts from any hardware store.

✅ No Welding Needed: Can be bolted together instead of welded.

✅ High Pressure Possible: Multiple screws allow for strong downward force.

✅ More Control: You can apply gradual pressure by turning screws evenly.

✅ Durable: No risk of hydraulic failures or expensive components.

✅ Modular: If one screw wears out, replace it cheaply.

#

Parts Needed (Easily Available)

#

1. Screws for Pressing Mechanism

- Large anchor bolts, concrete screws, or thick threaded rods (~16-20mm diameter, 30-50 cm long).

- You need at least 4–6 screws, but more screws = more even pressure.

#

2. Metal Pressing Plate

- A thick steel plate (8-12mm thick) with holes drilled for the screws to pass through.

- The plate moves downward as the screws are turned.

#

3. Perforated Metal Bottom (Oil Drainage)

- A strong, thick metal plate with small holes (~1-2mm) drilled into it.

- This allows oil to drip through while keeping solid seed cake inside.

#

4. Metal Frame

- A sturdy metal or wooden frame to hold the screws in place.

- Can be bolted together using angle iron.

#

5. Turning Handles (Optional)

- Weld handles to the screws, or use a long bar to turn all screws at once.

- If using threaded rods, you can attach a metal bar across multiple screws to turn them evenly.

#

How to Build It

Build the Frame

- Use steel L-beams or thick wood to make a strong, rigid structure.

- Ensure vertical support to hold the screws in place.

Attach Screws to the Pressing Plate

- Drill holes in a thick metal plate and pass the screws through.

- Weld or bolt a horizontal bar across the tops to turn all screws together.

Create the Pressing Chamber

- Below the pressing plate, place a steel container with holes at the bottom (for oil drainage).

- Reinforce the container to withstand pressure.

Add a Collection Tray

- Place a metal tray underneath to collect the dripping oil.

Test and Adjust

- Add seeds, turn the screws gradually until oil starts flowing.

- Make sure screws apply even pressure.

- If necessary, use thicker steel for the base to prevent bending.

#

Why This Works

🔩 Screws can generate huge force—like a car jack, but simpler.

🛠 Easy to repair—no expensive parts or special tools needed.

🌍 Accessible anywhere—anyone with basic tools can build this.

🚀 This is an excellent alternative to hydraulics! Would you like a diagram for this version?

To automate the multi-screw press using an engine or motor, we need a system that can rotate multiple screws at the same time without using complex gears. Since the screws are simply pressing down, we don’t need high-speed rotation—we just need slow, high-torque turning.

#

How to Power the Screws Automatically

#

1. Belt & Pulley System (Best DIY Option)

✅ Simple & Cheap—uses standard parts like belts and pulleys.

✅ Good for Low-Speed, High-Torque Rotation—exactly what we need.

✅ Easy to Repair—if a belt breaks, just replace it.

How it Works:

- Attach a pulley to each screw’s top end.

- Connect the pulleys using a single belt.

- Power the system with a slow-turning engine (7.5 kW is perfect).

- The engine turns a main drive pulley, which rotates the belt, turning all screws at the same time.

🔧 Parts Needed:

- One large main pulley (connected to the engine/motor).

- Multiple smaller pulleys (one for each screw).

- A strong rubber belt (from an old car engine, treadmill, or conveyor).

- Adjustable tensioner to keep the belt tight.

#

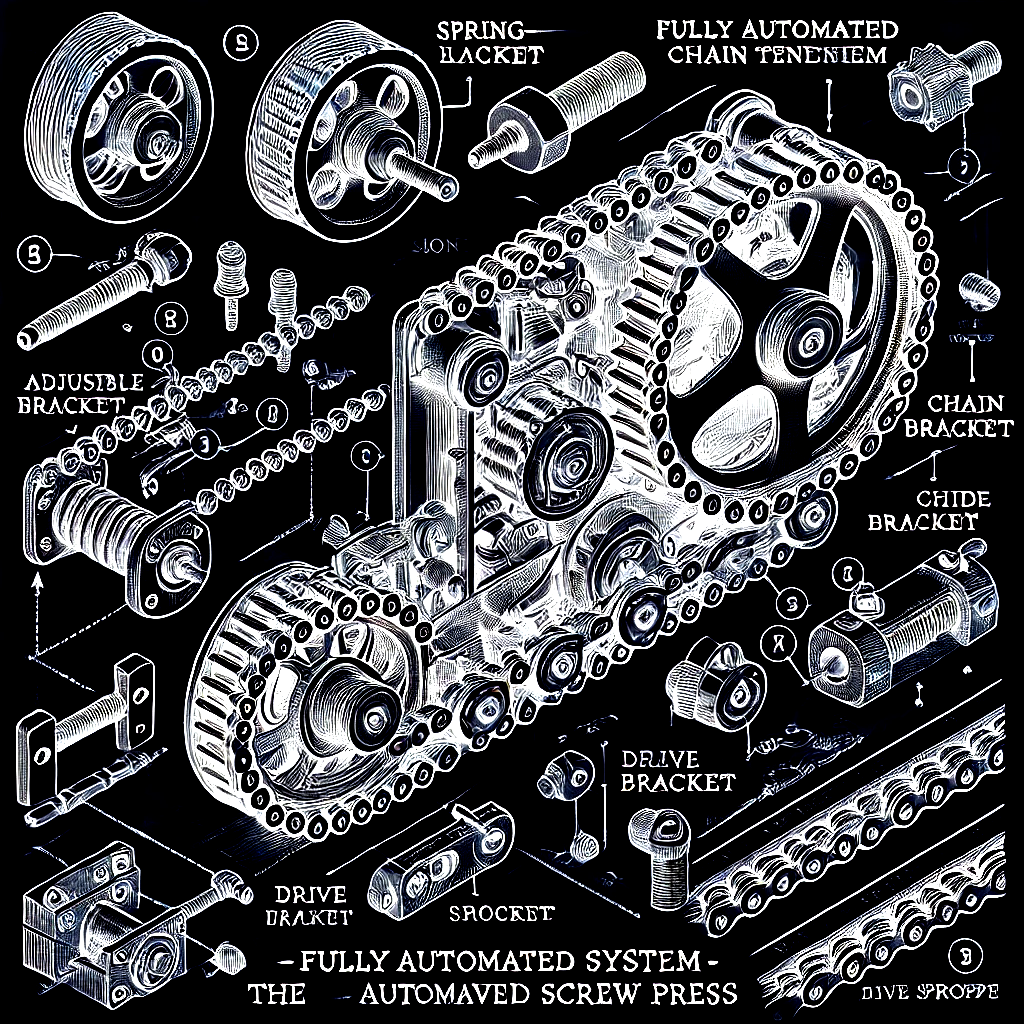

2. Chain & Sprocket System (More Durable)

✅ Better for Heavy-Duty Use—chains won’t slip under pressure.

✅ Handles Higher Torque Loads—good for hard-to-press seeds.

How it Works:

- Attach sprockets (like bike gears) to the top of each screw.

- Use a bike or industrial chain to connect all the sprockets.

- The engine/motor drives the main sprocket, which rotates the chain, turning all screws.

🔧 Parts Needed:

- Sprockets from bicycles or machinery.

- A strong chain (bike chain or industrial conveyor chain).

- Chain tensioner (can be a spring-loaded roller).

🔩 Bonus: If you use a motorbike chain & sprockets, you can get very high force with slow movement.

#

3. Worm Gear Drive (More Compact, More Expensive)

✅ Can Generate Huge Force with Minimal Space.

✅ Prevents Backward Movement (Self-Locking).

⚠️ Requires Precision Machining (Harder to Build DIY).

How it Works:

- The engine/motor drives a worm gear (a long screw with angled teeth).

- The worm gear turns geared rods, which screw downward.

- The system moves very slowly but with massive force.

🔧 Parts Needed:

- Worm gear (salvaged from old machinery, or bought).

- Geared rods (matched to the worm gear teeth).

- Engine-driven gearbox to reduce speed.

⚙️ This is what industrial screw presses use, but it’s harder to build without specialized machining tools.

#

Which System is Best?

#

How to Connect the Engine?

Attach a Drive Pulley/Sprocket to the Engine’s Shaft

- The 7.5 kW engine has a rotating shaft.

- Bolt a pulley or sprocket to it to drive the system.

Use a Speed Reducer (Very Important!)

- A generator engine turns too fast (1000+ RPM).

- A press should turn at 10–30 RPM.

- Use a gearbox, belt system, or pulley ratio to reduce speed.

Power the Screws Simultaneously

- If using belts, route a single belt around all screw pulleys.

- If using chains, use a multi-sprocket system.

Tension the System

- Use adjustable bolts or springs to keep belts tight.

#

Final Answer:

✅ Best DIY Setup: Engine + Belt & Pulley + Heavy Screws Pressing Down.

✅ Best Heavy-Duty Setup: Engine + Chain & Sprocket + Large Screws.

Would you like a diagram of the engine-driven screw press system? 🚀

#

If I have it correctly, the screws you'll sort of anchor at the top and the bottom so that they are steady. Then you'll attach a sprocket to each screw with a chain around each sprocket. So the screws will be turned with a sprocket with a properly secured screw that's secured at the top and the bottom so that the chain doesn't pull it sideways or skew. Is that about correct?

Yes, you’ve got it exactly right! Here’s how the setup works:

Anchor Each Screw at the Top & Bottom

- Each screw is mounted in place with bearings or bushings at the top and bottom.

- This keeps the screws aligned and prevents sideways movement when the chain pulls.

Attach a Sprocket to Each Screw

- A sprocket is fixed to each screw’s top or middle section.

- All the sprockets are linked by a single continuous chain.

Drive the System with an Engine

- The engine has a drive sprocket, which turns the chain.

- When the engine runs, the chain rotates all the screws at the same time.

As Screws Turn, the Pressing Plate Moves Down

- The screws drive the pressing plate downward, pressing the Moringa seeds.

- Oil flows out of the perforated base, while the seed cake remains in the chamber.

Reverse Rotation to Reset the Press

- The engine can be reversed (if possible) or a manual system can be added to lift the plate back up after pressing.

#

Key Design Considerations

✔ Use strong, thick screws (anchor bolts or threaded rods) → Prevent bending.

✔ Make sure the bottom mounting is solid → Use steel guides or bearings to hold the screws steady.

✔ Use a slow-moving engine or gearbox → The screws don’t need to turn fast, just steadily.

✔ Consider using a tensioner for the chain → Ensures smooth operation.

🚀 This setup is robust, simple to build, and fully automatic! Would you like a technical diagram of this chain-driven screw press system?

#

How would you keep these chains taut, so that they don't slack and then start pulling in different, well, all the chains would probably stay the same length because they were putting more pressure on some of them, and then you don't want some of them to start jumping, so you want them to stay, well, you don't want them to have lag. How do you keep them taut?

Yes, keeping the chain taut is critical to ensure even pressure across all screws and prevent slack that could cause uneven pressing or chain jumping. Here are the best ways to keep the chain tensioned properly:

#

1. Chain Tensioner System (Best Option)

✅ Simple & Automatic—Uses a spring-loaded tensioner to keep the chain tight.

✅ Prevents Chain Slipping & Jumping—Ensures constant engagement with sprockets.

✅ Easy to Maintain—Can be adjusted or replaced if needed.

How It Works:

- A small roller or sprocket is mounted on a spring-loaded arm.

- The roller pushes against the chain, keeping it tight as pressure varies.

- As the screws move, the spring compensates for any changes in length.

🔧 What You Need:

- Small sprocket or roller wheel (from a bicycle or machine).

- Strong spring (from an old car suspension, garage door spring, or farm equipment).

- Adjustable bracket (to fine-tune tension manually).

#

2. Adjustable Tensioner Bracket (Manual)

✅ Good for Initial Setup & Fine Adjustments.

✅ Simple to Build & Maintain.

⚠️ Requires Occasional Manual Adjustment.

How It Works:

- The main drive sprocket or an idler sprocket is mounted on an adjustable bracket.

- You loosen the bracket, pull it tight, and lock it in place when the chain is properly tensioned.

- If slack develops over time, you readjust manually.

🔧 What You Need:

- Sliding mount for the main sprocket (elongated bolt slots for adjustment).

- Locking bolts to keep it secure.

#

3. Chain Guide System (Prevents Skewing & Jumping)

✅ Ensures Chain Stays in Place.

✅ Works with Any Tensioning Method.

How It Works:

- Metal or plastic chain guides are placed along the chain path to keep it aligned.

- Guides prevent sideways movement that could cause uneven force on screws.

🔧 What You Need:

- Steel or UHMW plastic strips to act as chain guides.

- Bolts & washers to mount the guides near the sprockets.

#

4. Dual-Chain System (Redundant Backup)

✅ Distributes Load Evenly.

✅ Prevents One Side From Taking More Force.

⚠️ More Complex to Build.

How It Works:

- Instead of one chain, use two chains running parallel.

- This ensures equal force on all screws, reducing stress on any single chain.

🔧 What You Need:

- Two synchronized chains (each running on a mirrored sprocket setup).

- Dual chain tensioners to keep both chains tight.

#

Best Setup for Your Press

For a DIY automatic screw press, I recommend:

✔ Spring-Loaded Chain Tensioner (Automatic adjustment).

✔ Adjustable Mount on Main Sprocket (Fine-tune chain tension).

✔ Chain Guides (Prevents misalignment).

Above is a full technical diagram of the fully automated chain-driven screw press for extracting Moringa oil. It includes all major components such as the engine, chain drive system, screws, pressing plate, oil collection tray, and seed cake discharge area.

separate diagrams for each major part, including:

- The chain tensioning system

- The screw press mechanism

- The chain drive system

Here are the full system diagram and separate diagrams for each major part:

- Full System Diagram – Shows the entire automated screw press system.

- Chain Tensioning System – Ensures the chain stays taut for smooth operation.

- Screw Press Mechanism – Details the pressing plate, screws, and oil collection system.

- Chain Drive System – Illustrates how power is transferred from the engine to the screws.

#

Tell me how this thing works, so that a person that is hearing it for the first time should understand. Just tell it like a person that doesn't know much about engines, doesn't know much about what sprockets are, or how pressure works.(Maunita, ek weet julle weet, van die goed, maar net sodat ons op diesefde bladsy kom, het ek gevra dat hy 'n maklike verduideliking gee) But, why does this work? Why is this a good idea? Why is it cheap, and how long will it last? Is it durable? How long will the engine last? Will it be cost-effective?

#

How This Automatic Screw Press Works (Explained Simply)

Imagine you want to squeeze the oil out of Moringa seeds. If you squash them with your hands, only a little oil comes out, and it takes forever. But if you apply a lot of pressure, like squeezing a wet sponge hard, much more oil comes out.

This machine does exactly that—it presses the seeds very hard until the oil comes out. Instead of using human strength, it uses big screws and an engine to create powerful downward pressure.

#

How It Works, Step by Step

1️⃣ Seeds Go In

- You pour Moringa seeds into a container at the top of the press.

- These seeds are sitting on a metal plate with small holes at the bottom (like a strainer).

2️⃣ Screws Push Down the Pressing Plate

- On top of the seeds, there is a heavy metal plate.

- The plate is connected to several big screws (like giant bolts).

- When the screws turn, they move the plate downward, pressing on the seeds.

3️⃣ The Engine Turns the Screws

- Instead of turning the screws by hand, we attach sprockets (small metal wheels with teeth) to each screw.

- These sprockets are all linked together by a chain, just like a bicycle chain.

- A small gasoline or diesel engine (about the size of a generator engine) turns the main sprocket, which makes all the screws turn at the same time.

- As the screws turn, the pressing plate moves down and squashes the seeds harder and harder.

4️⃣ Oil Drips Out Through the Holes

- Because the plate is pressing down, the seeds get crushed, and the oil starts to drip out.

- The oil flows through the small holes into a collection tray at the bottom.

- What’s left behind is a dry, compressed “seed cake” (which can be used as animal feed or fertilizer).

5️⃣ Reset the Press

- Once all the oil is extracted, the engine reverses the screws (or you lift the plate manually).

- The dry seed cake is removed, and the press is ready for the next batch.

#

Why This is a Good Idea

✅ It’s Cheap to Build

- Uses simple parts: screws, chains, metal plates, and an engine.

- No need for expensive hydraulic pumps or high-tech equipment.

- Most parts can be bought from a hardware store or salvaged from old machinery.

✅ It’s Strong and Durable

- The engine can run for years with basic maintenance.

- The screws are thick steel, so they won’t bend or break easily.

- The chain system is the same kind used in motorcycles, designed for long-term use.

✅ It Saves Time and Labor

- Instead of pressing oil by hand, this machine does it automatically.

- One person can run the press alone, making it great for small businesses.

✅ It Produces More Oil

- This system extracts almost all the oil from the seeds.

- Manual pressing or weak machines waste oil, but this press gets the maximum yield.

✅ It’s Easy to Repair

- No complex electronics—just an engine, screws, and chains.

- If something breaks, any mechanic or welder can fix it easily.

#

How Long Will It Last?

- The Engine: If well-maintained (oil changes, clean fuel), it can last 5–10 years.

- The Screws & Pressing Plate: Made of thick steel, so they can last decades unless rusted.

- The Chain Drive: Should last 5+ years if lubricated properly.

- The Frame & Plates: Indestructible if made of good steel.

With regular maintenance, this machine can work for 10+ years without major problems.

#

Is It Cost-Effective?

✔ Buying a Commercial Press: Costs R50,000–R200,000 (too expensive).

✔ Building This Press: Costs R10,000–R20,000 (depending on parts used).

✔ Profit Potential:

- 1 ton of Moringa seeds = 250 kg of oil.

- If oil sells for R1800/kg, that’s R450,000 per ton of seeds.

- The machine pays for itself after processing just one ton of seeds.

#

Final Thoughts: The Perfect Business Machine

🚀 It’s Cheap—Anyone with basic tools can build it.

💪 It’s Durable—No complex parts, built to last years.

💰 It’s Profitable—Extracts maximum oil with minimal labor.

This is a great investment for small businesses looking to produce high-value Moringa oil at a low cost. Would you like a *detailed parts list and step-by-step build guide?